Forums › NCR Members Area › Swap Meet › Stainless 1515 rail buttons

- This topic has 31 replies, 13 voices, and was last updated 17 years, 8 months ago by

Warren B. Musselman.

Warren B. Musselman.

-

AuthorPosts

-

2008-03-23 at 10:23 pm #40181

Warren B. MusselmanModerator

Warren B. MusselmanModeratorSince I’ve been playing with machine tools lately, I decided to make up some rail buttons for my L3 project. They were made on an NC lathe and so since I only need a couple sets, I have 10 sets available right now for sale or the appropriate trade. (It’s gotta be something I want). I also have materials left to make another 24 of them and the program to make them so I can turn them out of Delrin, aluminum or stainless in the future.

I’m thinking $20 a pair including the 3/4″ stainless 10-24 phillips flat head screws. This covers my materials cost and the tooling costs I have to pay my company and it still gives me about $5 a pair for the effort. I have 10 pairs available and I still have another 3 foot stick of stainless so I can make more if demand is there.

2008-03-24 at 4:05 am #47333

2008-03-24 at 4:05 am #47333Bruce R. Schaefer

Warren, those look fantastic! Any chance of getting a hole to fit a 1/4-20 bolt? Your prices are more than reasonable! Very nice!

2008-03-24 at 4:13 am #47334 Warren B. MusselmanModerator

Warren B. MusselmanModeratorNot for the 1515 style buttons – the shaft diameter precludes it.

I’m thinking of making some Unistrut buttons somewhere down the road and those would take a 1/4-20 flathead screw. I’ve also got a program written to do 1010 sized buttons, but those use 8-32 screws and quite frankly, stainless buttons are a bit overkill for anything that flies off 1010 rail I think.

It would be possible to drill or ream out the hole on these for a 1/4-20, but the countersink is set up specifically for standard 90 degree 10-24 or 10-32 flathead machine screws so you’d have a problem with clearance for the screw head.

W

2008-03-24 at 4:34 am #47335Bruce R. Schaefer

Gotcha… I wouldn’t use those beauties on a 1010 rail. L3’s only use 1/4-20’s. I can wait. 😉

2008-03-24 at 12:56 pm #47336 Warren B. MusselmanModerator

Warren B. MusselmanModeratorWhaddya mean L3’s only use 1/4-20’s?. Two 10-24 stainless screws should be able to easily hold 300# before deformation. I used to have a table around here somewhere and the individual screw needs over 300# before deformation begins for even a single screw.

W

2008-03-24 at 1:56 pm #47337 Doug GerrardParticipant

Doug GerrardParticipantWarren, I’m surprised the club would let you use them on their rail. I thought most clubs prohibited the use of metal rail button because it galls the rails. I guess most people figure its easier to replace the rail buttons as needed than to replace the rails.

Doug

2008-03-24 at 2:07 pm #47338Anonymous

FWIW, about ten? years ago, Black Sky gave away free rails to all clubs who asked for them. This is still when PHITS and TRM (the predecessor clubs to NCR) were in existence. Both PHITS and TRM ordered and received rails. One of the rails is still in the trailer.

One of the items Black Sky offered was metal rail buttons. Many of us starting using those buttons way back then. I’d guess they have flown many, many dozens of flights on the rails. They were anodized aluminum (not stainless) but metal all the same. I’ve flown them myself, as have others in the club. The rails seem to be none the worse for wear.

Doug, I understand your concern, especially since you definitely have the coolest pad I’ve ever seen and I’d surely understand your decision to not let them fly on your rail. Were I you, I’d probably have a similar ban. That said, we haven’t had any wear on the NCR rails. I check them every single time I load a rocket. So far, so good.

Sidebar – does anodization harden aluminum? It surely seems to, but my evidence is anecdotal.

2008-03-24 at 2:10 pm #47339 Warren B. MusselmanModerator

Warren B. MusselmanModeratorThese are fully polished rail guides so I guess I don’t see an issue. Besides, I’m one of the two equipment managers and the rails are, amongst other things, my responsibility and I see the kind of damage they take. The wire brushing used during the cleaning parties does far more damage to the rail surface than these rail guides ever will. Personally, I was sick of my delrin buttons and even aluminum buttons getting all munged up from the old NCR rails. I’ve seen many other flyers using all metal buttons both here at NCR and various other places including birds I’ve seen in national magazines.

W

2008-03-25 at 4:37 am #47340Kenneth Reilly

ParticipantJW,

Since you asked… Anodizing oxidizes the outer skin of the aluminum. There are at least two types, with one being more porous and therefore softer than the other. Hard anodizing produces a fairly dense outer layer of aluminum oxide. There are only a handful of substances harder than aluminum oxide ( Diamond, Boron Carbide, Silicon Carbide, Boron Nitride). While aluminum oxide layer is very hard it is also very thin… maybe .0001 to .0003″ thick.

2008-03-25 at 9:03 pm #47341slipstick

A few launches with buttons that are harder than the rails would show negligible wear, but if the concept became popular and widespread, than it would become an issue in the life of the rails

So, if you don’t mind me chiming in here, as a mechanism designer, I’ll try to clarify some points I’ve seen made. The 1st white paper I ever wrote (1984) was about metal to metal friction of sliding and rotating forces as part of a development project I was on as a rookie engineer. The optical disk drive did not allow for lubricants in the cartridge mechanism that could propagate to the media. A variant of this drive was installed in MIR where lubricants were avoided. I also was part of several library designs that had to achieve millions of cycles.

In essence galling is an advanced form of wear that is dependent on surface finish (friction), contact pressure, the relative velocity between the contact surfaces (speed) and the number of repetitive cycles. Additionally, material selections can affect the life of the mechanism, as one material will become sacrificial to the other. No friction, no force, no speed, no problem.

In the case of launch rails with two guides, the contact pressure is very low as the horizontal force vector is only .0002 times the motor thrust (based on the cosine of 1 degree derived from potential slop in the rail compared to an arbitrary distance between rail buttons). However sideways wind forces that cause the rocket’s buttons to bind in the T-slot would increase the force dramatically.

Velocity plays a giant part, especially as the upper button leaves the rail and any instability and cross wind forces that are aligned with the plane between the rocket and rail that could increase binding forces. The upper section of the rail would take the brunt of the force and have more wear than further below. Note that the binding on the lower button would be minimal, once the upper button has left the rail, if the wind is crosswind or normal to the rocket/rail plane.

In mechanism designs, using removable cartridges in a disk drive as an example, the burden of wear is put upon the removable component (the cartridge) not the drive itself. The cartridge might be designed to handle 50 insertions in its life but the drive must allow for over 2000 cycles. The less expensive part gets thrown away and replaced, rather than the more expensive assembly.

In the case of the 8020inc Sulfuric Anodized aluminum rails, the 204R1 Sulfuric anodizing is only .0004″ thick (50% penetration into the substrate and 50% growth). It is more for appearance rather than wear like hard anodizing offers and can be .005″ thick. Once this surface is damaged, additional damage would occur exponentially, again depending on friction, force, speed and the number of launches.

Granted, the number of handlings, tool marks, cleanings and environmental conditions (dust and rocks) have created a less than ideal surface on the existing rails, but a button made of a polymer material will not make it worse. Aluminum buttons would be horrific in this case, followed by steel. Unpolished contact surfaces (those with circular tooling marks from the lathe) would become abrasive files.

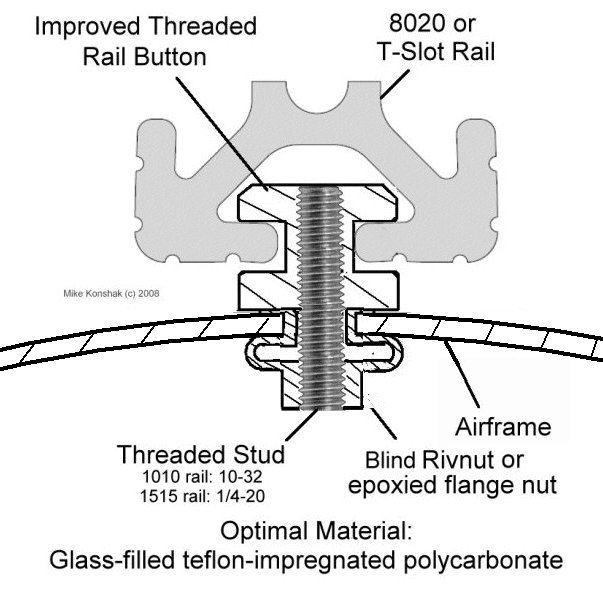

As an alternative (I’m not happy with what is currently available rail buttons either, although I love PML’s concept) is the following design which uses the maximum size studs for the 8020/T-Slot rail profile and eliminates the potential screw head interference, which bit me the first day I showed up on at the Atlas site with Slipstick III.

The threaded button, if polycarbonate is used, can be securaly fastened to the stud with Loctite and other adhesives (Delrin and Nylon are hard to stick to). If damaged the button/stud can be replaced. Current embodiments of the rail button will mushroom out the center section between the flanges if tightened very much, which will bind on the rail, but in this design that occurrence is not possible. The larger screws will withstand higher launch forces than other options.

When installing Rivnuts I would suggest putting some JB weld around the edge of the hole to keep the insert from spinning later after a lot of use.

So if someone has a buddy with a screw machine, I wouldn’t mind getting a handful of the above. Actual dimensions on request.

FYI, In the U.S. common UNC and UNF flat head machine screws all have 82 degree heads, and Aerospace fasteners are all 100 degrees for thin sheetmetal). Hardened screws used in tooling can use 110 and 120 degrees. Only wood screws and metric machine screws use a 90 degree countersink.

-

AuthorPosts

- You must be logged in to reply to this topic.